Remanufactured, rebuilt, refurbished, and reconditioned—these all sound similar when it comes to purchasing pre-owned pumps, parts, and other rotating equipment. Any of these solutions can provide you with significant savings compared to buying a brand new unit. However, it is important to understand what each solution means so you have more information about any used pump equipment you’re considering purchasing for your operation.

Remanufactured and refurbished are the two terms you tend to hear most, but four different methods can be implemented to restore old equipment. Which solution a manufacturer or repair shop uses may depend on the condition of the pump or specific components inside. Here are the descriptions you need to know:

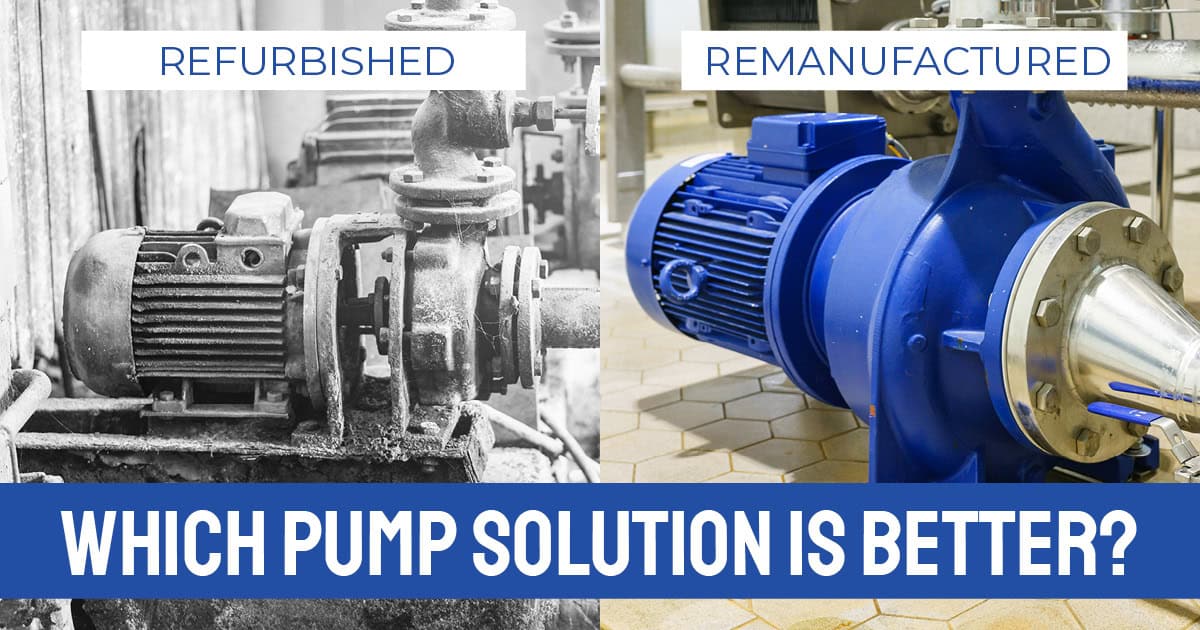

Refurbished Pumps

Refurbishing is generally the simplest option when a defective product has been lightly used—or sometimes never used. It may simply be a cosmetic issue or something relatively easy to fix. Refurbished equipment generally doesn’t require any part replacements or component rebuilding within the pump.

Rebuilt Pumps

Rebuilding a pump or other piece of rotating equipment is a more involved process compared to refurbishment. The equipment is dismantled so each part can be inspected. All parts in good working condition can then be cleaned and reinstalled. Meanwhile, damaged or worn parts are replaced with new or refurbished parts. Not all internal parts are replaced during a pump rebuild, so they will have different levels of wear. The rebuilt equipment should run well, but it may only be a matter of time before it can fail again, as different parts wear out beyond effectiveness.

Reconditioned Pumps

The closest you will find to a remanufactured pump is a reconditioned unit. Like a rebuild, the equipment is dismantled, and each part is professionally inspected, tested, and cleaned. However, all worn parts are replaced or reconditioned to restore every component to original working condition. A reconditioned pump cannot use the product’s original warranty from the manufacturer but may carry its own warranty because it is back to the original specifications. This may provide more peace of mind and a longer equipment lifespan compared to refurbished or rebuilt pump equipment.

Remanufactured Pumps

The highest standard of pump equipment restoration is remanufacturing. It is a similar process as reconditioning in that any worn parts are replaced. However, the goal of pump remanufacturing is to bring the equipment back to the manufacturer’s original specifications or even higher standards. DXP remanufactured pumps adhere to strict dimensional tolerances and are often customized for hydraulic needs or configurations based on the specific pump application. This is why pumps remanufactured by DXP come with an exceptional warranty program, which often exceeds the OEM warranty.

Benefits of Remanufactured Pump Equipment

Remanufactured pumps and parts can provide a number of key advantages, including extended lifespan, minimal waste, and strong warranty coverage. While remanufacturing doesn’t always result in significant cost savings compared to new pumps, its primary advantage lies in lead time savings. This can significantly benefit production timelines, typically by 8-12 months.

If you have the option available, remanufactured pumps and parts should be your first choice for extended durability and performance. Reconditioned, rebuilt, and refurbished equipment may save you a little more money and may be the right choice based on your needs and budget. It’s important to understand the differences and make an educated decision.

For all your pump selection needs, contact the team at DXP Quadna today.