The Lower Pinal Creek wastewater treatment plant is located north of Globe, Arizona. Worley Field Services operates the facility, and Freeport-McMoRan funds it. The location of the plant faces some unique challenges as the area is within the Globe-Miami copper mining district. The ground is rich with copper, as well as traces of molybdenum, manganese, zinc, gold, and silver. These minerals and precious metals can be difficult on wastewater pump equipment—especially when that equipment is outdated.

DXP Quadna Serviced Obsolete Equipment Until Plant Reached Out to Replace Pumps

Most of the original rotating equipment at the Lower Pinal Creek plant is from the late 1990s. It has been obsoleted, and the original manufacturers no longer support it. They have relied on DXP Quadna since 2013 to service this equipment. Many parts for this older machinery have long lead times to track down or simply aren’t available anymore. DXP has been able to custom machine certain parts like shafts, sleeves, and clamp plates. Meanwhile, other parts became too difficult and expensive to procure.

The plant was long overdue for new pump equipment. They reached out to Garrett Beane in DXP Quadna’s engineered sales division to find a better long-term solution. Garrett has been with DXP Quadna since 2004. He started as an applications engineer before moving his way up to become an engineering manager—later shifting to his current engineering sales role.

Garrett enjoys that no two days at DXP Quadna are ever exactly the same. Clients frequently come to him searching for solutions to different challenges. He and the engineering team are always up to the task.

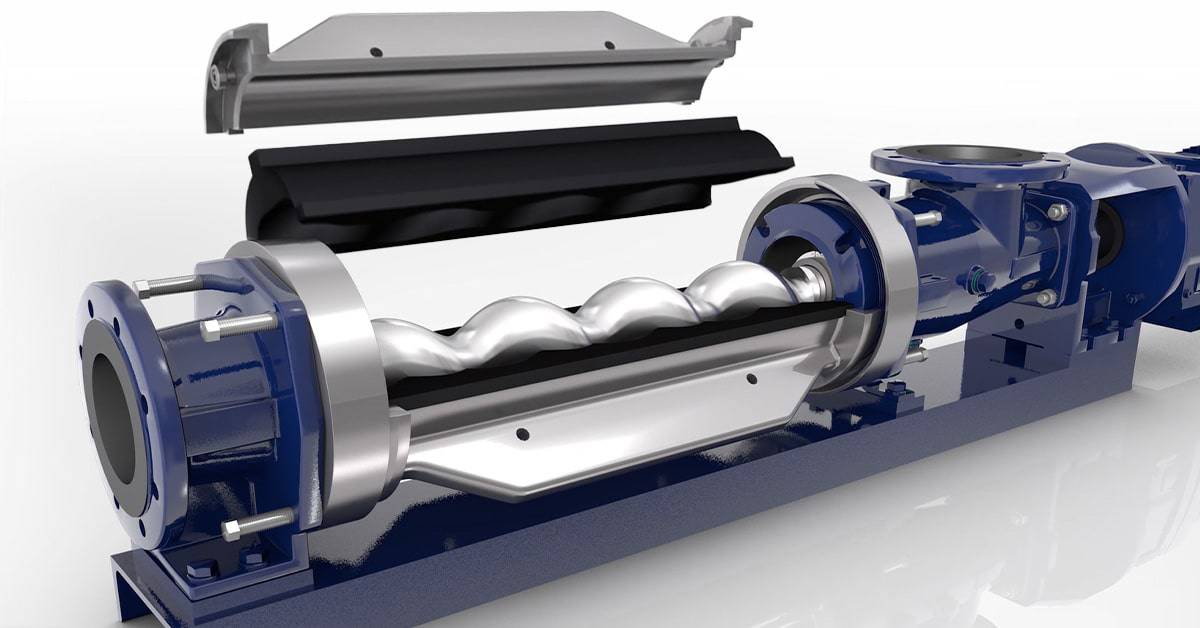

SEEPEX SCT Pumps: The Right Technology

Garrett previously met with the maintenance team for the Lower Pinal Creek plant to provide a demonstration of SEEPEX Smart Conveying Technology (SCT). This line of pumps offers fast, simple maintenance to minimize downtime and reduce life cycle costs. The Smart stator and rotor are each manufactured in two pieces. This allows the pump to be maintained without needing to remove the suction or discharge pipe work. In addition, SEEPEX SCT pumps provide excellent conveying capacities and pressure ratings thanks to the adjustable sealing line between the stator and rotor.

SCT pumps from SEEPEX were the ideal technology for the problems the treatment plant faced. When it came time to replace their old pumps, the choice was simple. Installation of the new pumps went smoothly because they were nearly a direct drop-in replacement.

New Pumps Improve Performance at Wastewater Treatment Plant

The Lower Pinal Creek wastewater treatment plant has experienced drastically improved pump performance since the installation of these new SEEPEX SCT pumps. In addition, the adjustability of the pumps’ design has significantly reduced maintenance time. Replacement parts are easier to receive and faster to deliver. DXP has had an excellent relationship with SEEPEX for over a decade. Many of our clients use their equipment, and we know they are extremely reliable when it comes to shipping and customer support.

The client was so pleased with the result of this pump replacement project that they recently approached Garrett about replacing another set of smaller outdated pumps. Even several maintenance personnel who are no longer working at the Lower Pinal Creek plant continue to contact him and DXP Quadna for support at their new locations.

The team at DXP Quadna is committed to finding the best solutions for our clients. You can count on our engineering experts to make the best decisions when it comes to pump equipment installation, maintenance, and repairs. To learn more about our services throughout the Southwest and Rocky Mountain regions, contact us today.